Production

Outstanding materials are created when know-how and commitment come together. Together, we continue to develop proven production standards and establish new, innovative processes in order to produce even more safely, economically and resource-efficiently.

Production route

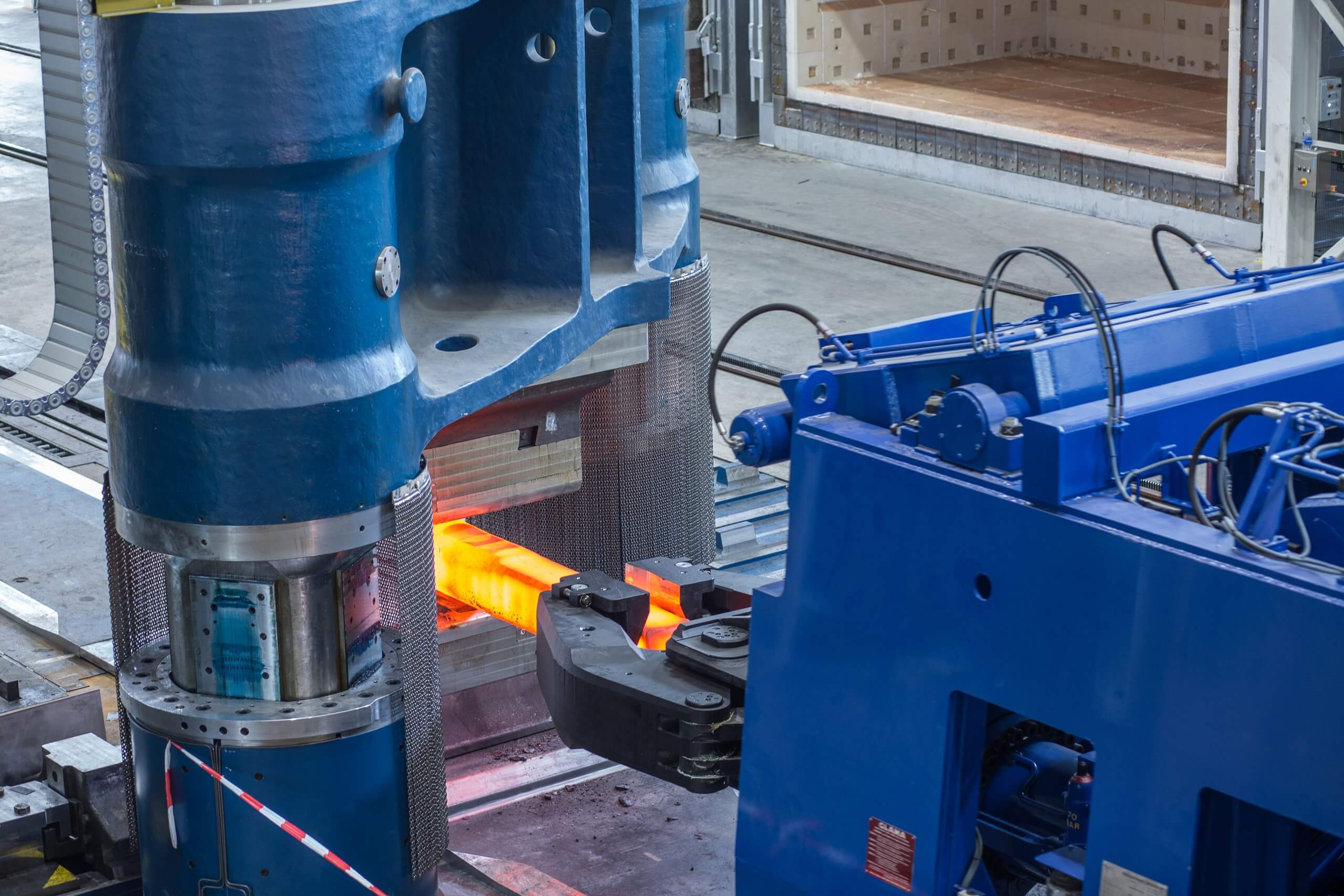

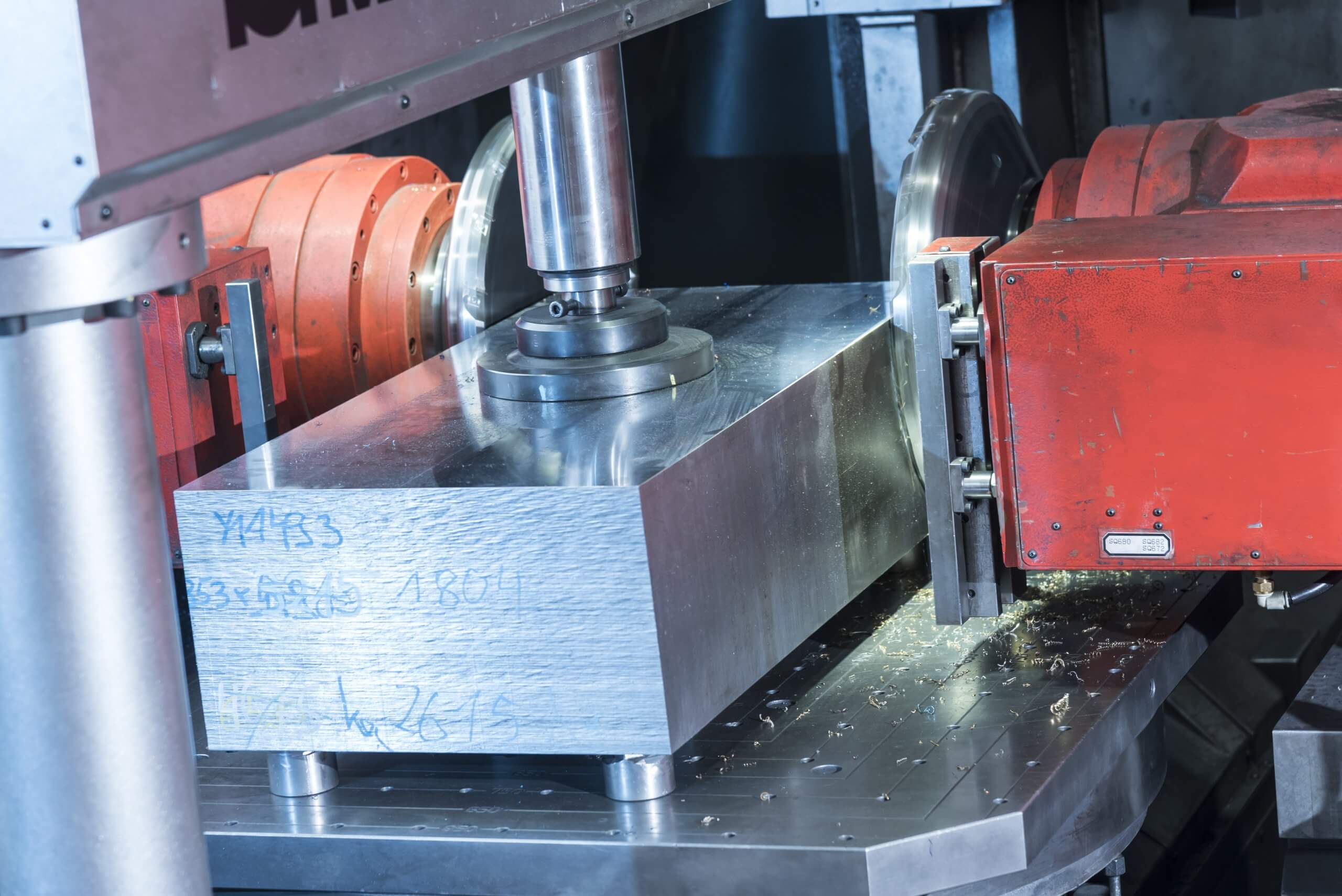

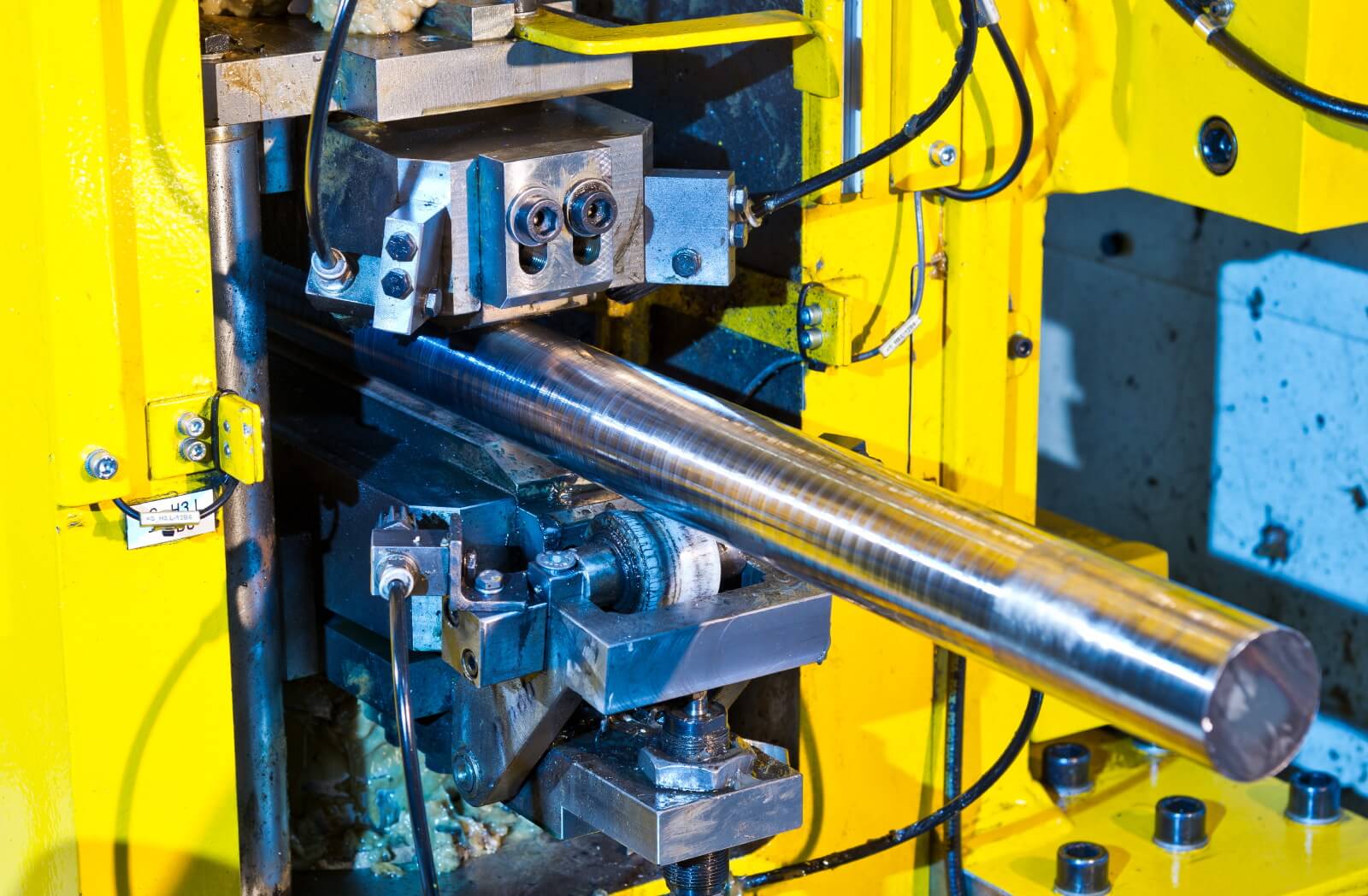

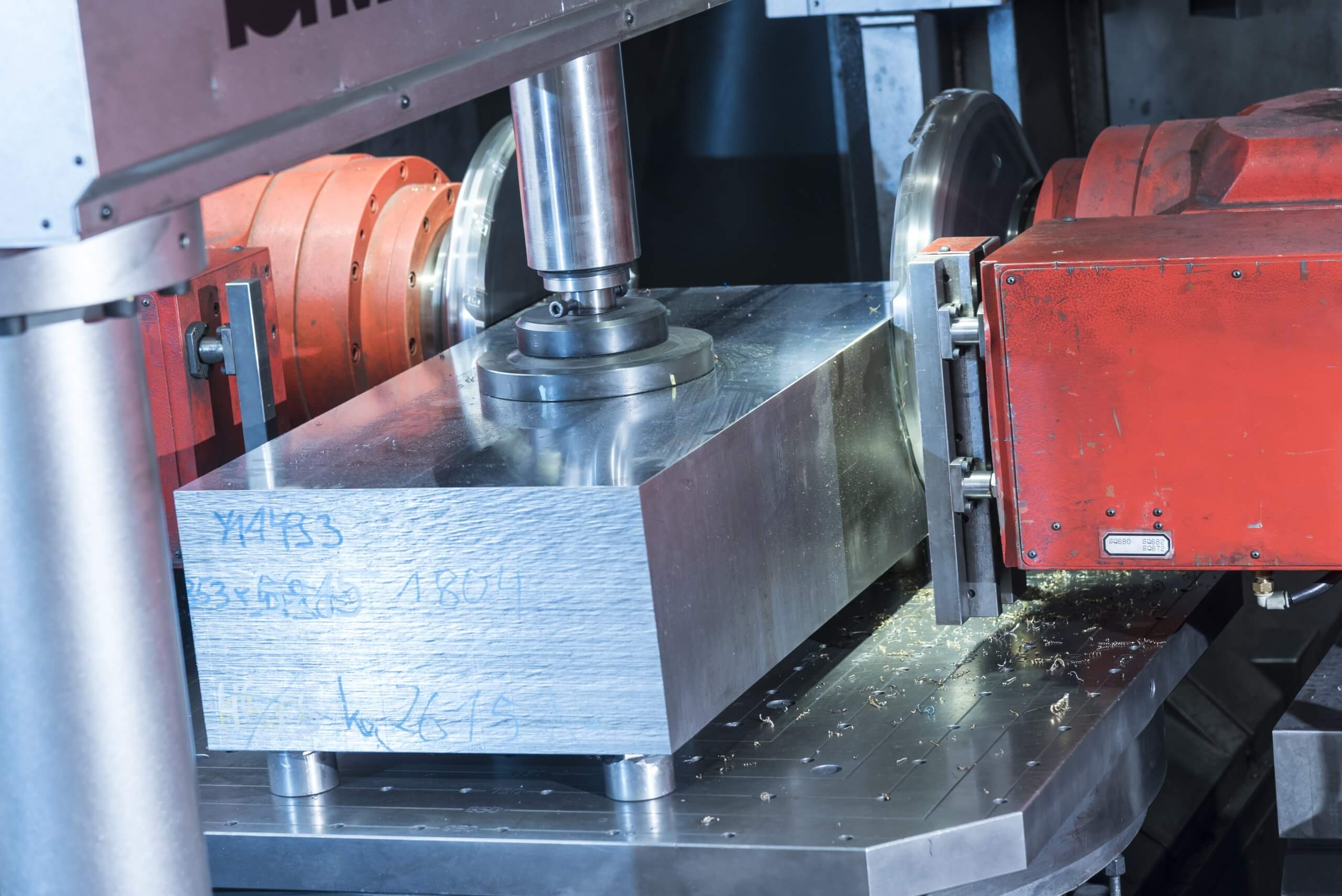

Our production processes are based on state-of-the-art technology and in-depth expertise. From melting and powder metallurgy to forming and machining – every process guarantees the highest quality and precision.

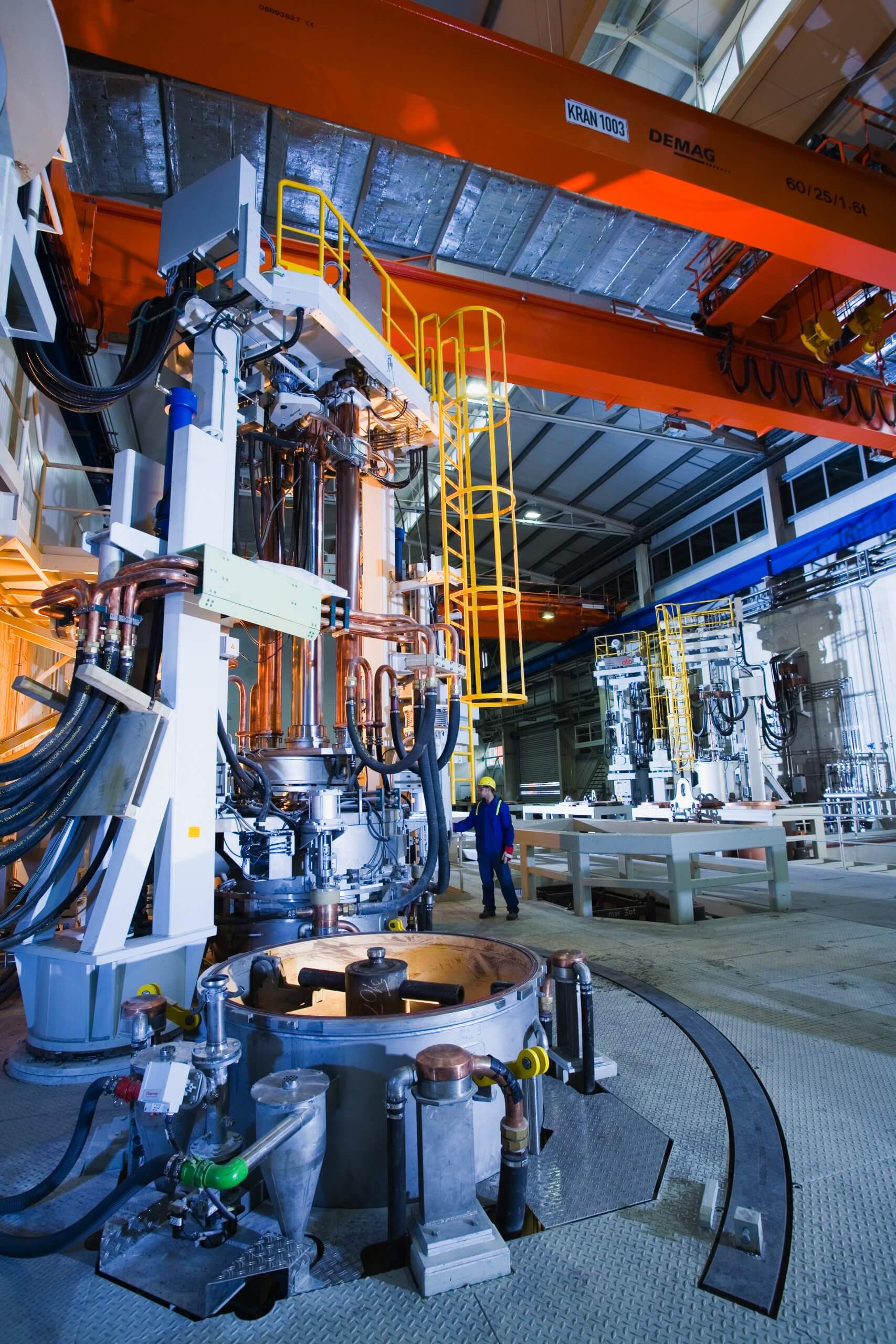

The new special steel plant

The opening of the world’s most modern stainless steel plant in October 2023 marks a technological milestone in the production of future-oriented high-performance materials for the international automotive, energy and aviation industries. The new plant is a global pioneer in terms of digitalization and sustainability.

The opening of the special steel plant in Kapfenberg is a historic moment and a decisive technological step for the voestalpine Group, enabling us to further strengthen our global competitiveness. At the same time, this major investment contributes to the long-term preservation of prosperity and jobs in the region.

Milestones in the construction of the new stainless steel plant

-

09.2017

Decision on location

-

04.2018

Groundbreaking ceremony

-

07.2018

Award of technological plant construction for melting area to SMS group

-

Q4 2018

Award of plant construction for casting area and hall construction

-

Q4 2018

Start of hall construction

-

From 2019

Installation of the units

-

End 2020

Start cold commissioning

-

2023

Start-up phase / commissioning